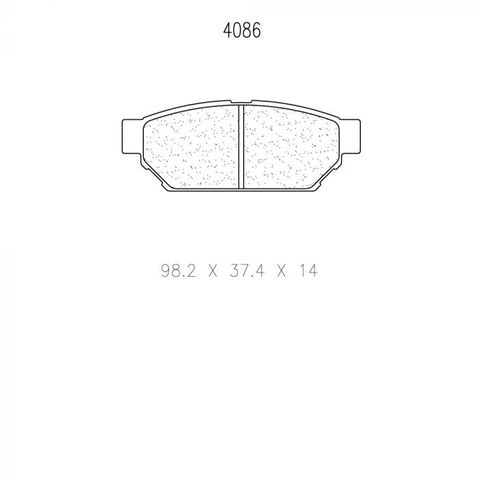

CL Brakes - Mitsubishi Lancer EVO 3 (Brembo Gravel) Rear Brake Pads

Description

CL Brakes (formerly known as Carbone Lorraine) are high performance sintered brake pads. These pads are used in the highest levels of motorsport worldwide. The pads are made of a unique sintered material resulting in all compounds having a very high friction coefficient and its uncompressible material gives a stiffer pedal and better brake modulation. Unlike other performance pads CL are gentle on the discs and require no specific bedding in procedure. One of its best features is that the pad material operates from cold and friction never decreases with high temperatures.

- Excellent friction/grip from cold

- Friction/grip doesn’t decrease with high temperatures

- No specific bedding in procedure necessary

- No material transfer

- Gentle on discs

- Very low wear rate

- Sintered metal compound brazed to high quality backing plate

- Environmentally friendly, no lead, no asbestos and no nickel

CL produce four different friction compounds:

RC5 Compound (Average friction coefficient µ = 0.4): This material in the range is particularly suitable for light car applications, thanks to its low wear rate in low grip race conditions (Gravel, wet, standard tyres etc…). Fitted in rear axle, it helps to get the right brake balance when brake bias adjustment is not possible. Easy to use for track day's thanks to its low noise level, moderate and very stable friction level, effective from cold and gentle with brake discs.

RC6 Compound (Average friction coefficient µ = 0.5): This popular compound can be used in almost every type of competition and provides a high and stable friction level. It can be used front and/or rear combined with the RC5 and RC8. The discs life is increased because there is no material transfer.

RC6E Compound (Average friction coefficient µ = 0.46): RC6 Endurance offers a good level of grip combined with extremely low disc/pad wear rate making this the winning combination for endurance races. As with the entire product range the bedding in process is easy and the performance is very stable from cold to high temperature.

RC8 Compound (Average friction coefficient µ = 0.6): RC8 compound is designed for the most demanding high performance cars, (WRC, Nascar, WTCC, ZA V8, GrpN…..). Very high and stable friction level which will shorten your brake distances. This compound should be used with another C.L pad for the rear axle. RC8 is also available with a grooved backing plate option (RC8-R).

RC8-R Compound: Uses the same friction compound as RC8 but features a grooved backing plate which is designed to provide a radiator effect the contact area with the calliper is reduced providing better heat transfer. This patented shape is particularly useful in cases of brake fluid temperature issues. Should only be used when vehicle has ventilated brake systems (air ducts).